Ancient Egyptian mirrors hold immense cultural and religious significance, yet their production methods have remained underexplored. While their symbolic and spiritual importance has captivated many, the technical aspects of their manufacture have only recently been subjected to rigorous study.

A recent study published in the Journal of Archaeological Science: Reports sheds light on the craftsmanship behind these fascinating objects. This research, led by Elizabeth Thomas from the University of Liverpool, delves into the metallurgical techniques employed by ancient Egyptian artisans.

The Study of Ancient Mirrors

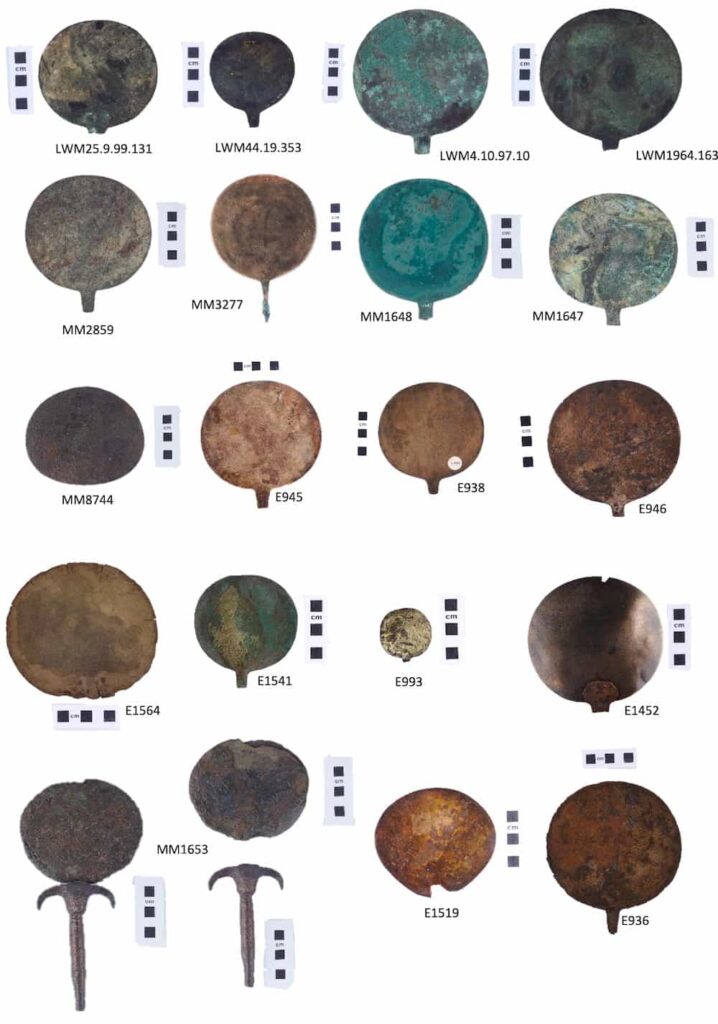

Thomas analyzed 19 mirrors from museum collections across the United Kingdom, spanning a vast timeframe from the Old Kingdom to the Late Period.

Employing advanced scanning electron microscopy paired with energy-dispersive X-ray spectroscopy (SEM-EDX), the study provided an in-depth examination of the mirrors’ chemical makeup and microstructures.

This groundbreaking research uncovered key insights into the alloys used by the Egyptians. Three primary materials were identified in the manufacturing process:

- Arsenical copper

- Copper-tin alloy

- A ternary alloy combining arsenical copper with tin

Consistency in Craftsmanship

One of the most remarkable findings was the consistent composition of the alloys. Most mirrors contained around 5% arsenic or tin, indicating a sophisticated level of standardization in the production process.

This uniformity highlights not only the metallurgical expertise of ancient Egyptian craftsmen but also raises questions about why these specific alloy compositions were favored.

Why These Alloys?

The study suggests that these compositions may have been carefully selected for their practical and aesthetic properties. The alloys offered a balance of hardness and malleability, ensuring durability while allowing artisans to shape the metal with precision. Furthermore, the resulting hues—golden or silvery—likely added to the visual allure and symbolic value of the finished mirrors.

Surface Enrichment for a Silvery Finish

One intriguing discovery from the study was the use of a technique called surface enrichment, found on several of the analyzed mirrors. This method involved creating an arsenic-rich surface layer, which imparted a silvery sheen to the mirrors. Such a finish may have been designed to mimic the appearance of costly silver, elevating the mirrors’ aesthetic and symbolic value.

The study suggests that this effect was achieved through reverse segregation, a complex metallurgical process requiring detailed knowledge of arsenical copper’s properties.

Symbolism and Religious Connections

The choice of alloys resulting in golden or silvery hues is thought to have carried religious significance. Mirrors were often associated with the sun god Ra, and their reflective surfaces may have symbolized the life-giving and divine qualities of the sun.

Standardized Craftsmanship

Microscopic analysis also revealed a highly consistent manufacturing technique. Craftsmen used repeated cycles of cold hammering and annealing to enhance the hardness of the metal. This process not only improved the durability of the mirrors but also allowed for superior polishing, resulting in a clearer reflective surface.

Remarkably, this standardized method was consistent across different regions and time periods, pointing to a well-established and widely practiced tradition of mirror-making in ancient Egypt.

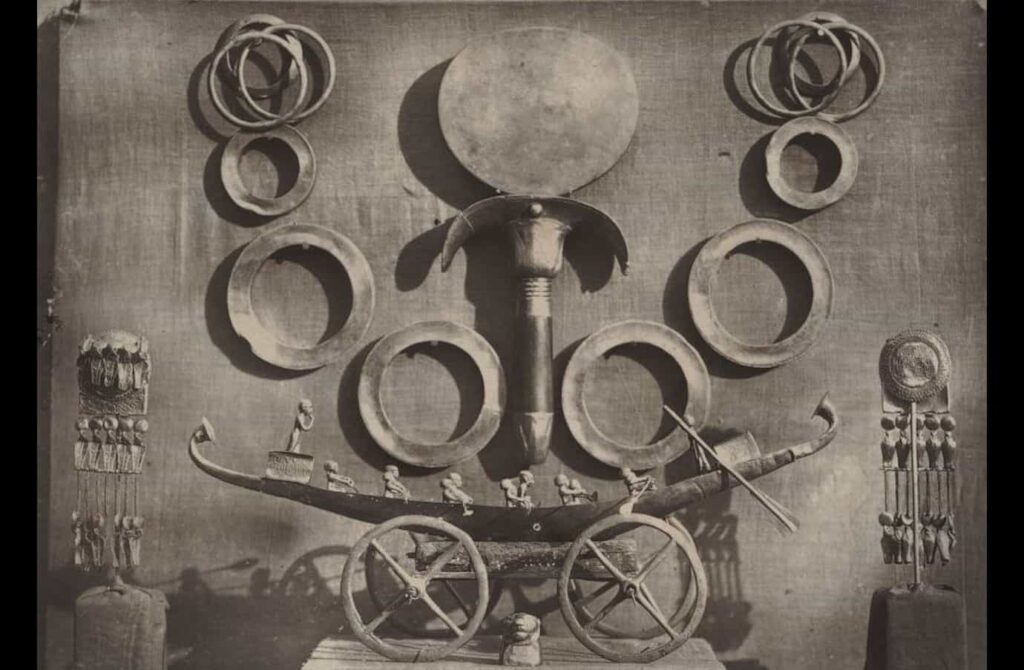

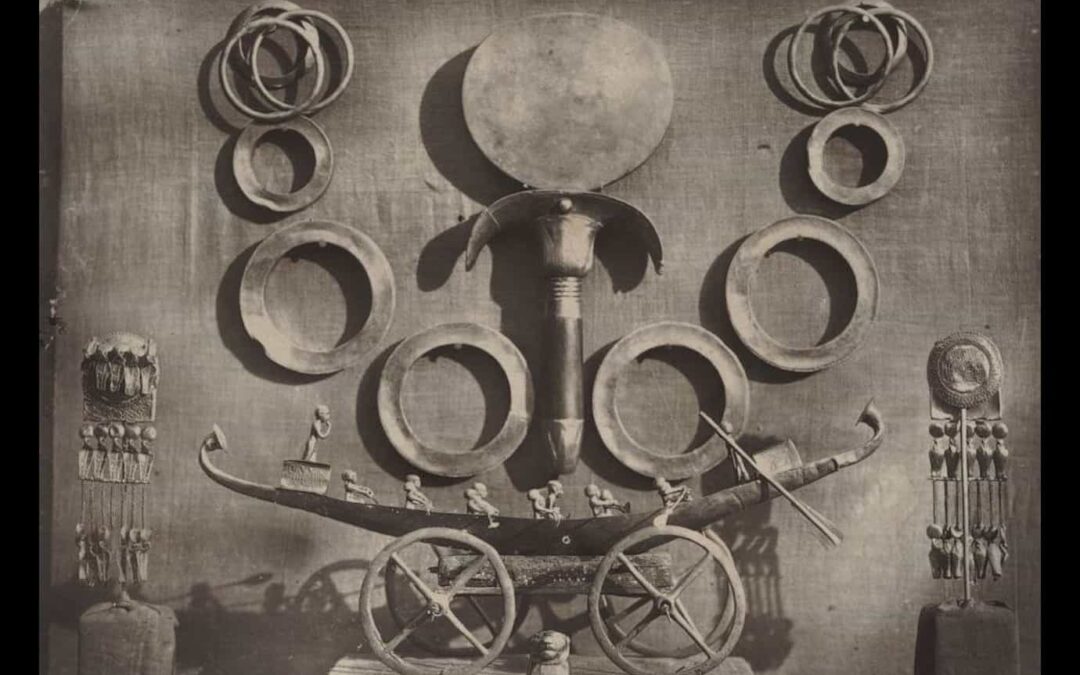

Miniature Mirrors for Tombs

The study also examined model mirrors, miniature versions created for burial purposes. These symbolic items were intended to serve as magical substitutes for real mirrors in the afterlife.

Interestingly, these models were crafted using the same techniques as full-sized mirrors, though slight variations in alloy composition suggest their purpose was more symbolic than practical.