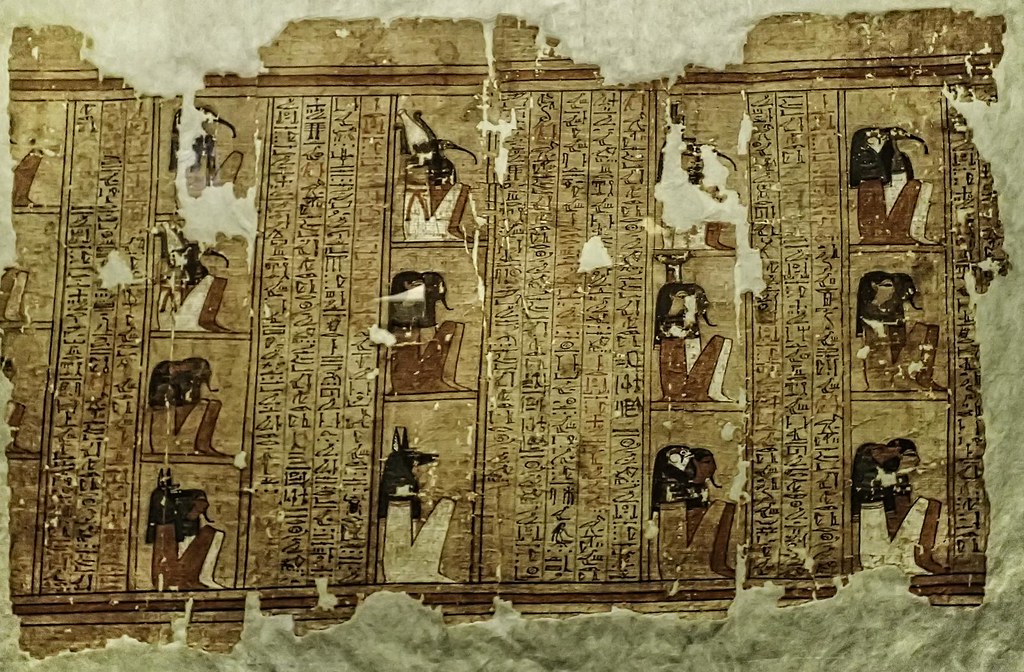

As you well know, for the ancient Egyptians, papyrus had enormous value and importance since it helped transform this society in different ways.

As the technology of making papyrus developed, its production method was kept secret so that Egypt would be the only place in the world where it was made. It is estimated that the first papyrus used in Egypt was 4000 years BC.

Why was papyrus so important to the ancient Egypt?

Papyrus is made with the Cyperus plant, which has always grown on the banks of the Nile River, offering the ancient Egyptians the raw materials necessary to perform this role, as well as boats, ropes and baskets, since its leaves and trunk are extremely versatile.

It was then that ancient Egypt became the most important exporter of papyrus in the world and in turn revolutionized the way of preserving valuable information since there was no substitute for this type of paper that was equally resistant and light, until the arrival of the development of the paper pulp of the Arabs.

Although the duration of the paper pulp created by the Arabs was not the same as that of the papyrus, its elaboration was much less complex to carry out, so for this reason the creation of the Egyptian paper was declining as the cultivation of the plants of those that obtained the raw material, disappearing from the Nile area.

Only in 1969 the manufacture of papyrus was resumed, it was the Egyptian scientist Dr. Hassan Ragab who reintroduced the Cyperus plantation near Cairo, as well as investigating the production methods revealing the secret that the ancient Egyptians had treasured under lock and key.

How was papyrus made in ancient Egypt?

- From the central part of the stem of the papyrus plant they extracted, with a blade, thin vertical strips. The size of the manufactured papyrus depended on the length of these strips.

- These thin strips kept them soaking for 7-14 days. The longer they soaked, the darker the papyrus became.

- The strips were beaten with mallets to flatten them. In this way they lost part of their water and sugar content, and gained strength, becoming less brittle.

- A first layer of strips was placed on a moistened flat tablet, to which another was superimposed perpendicularly, alternating several horizontal and vertical layers until forming a rectangular sheet.

- This rectangular sheet of papyrus was pressed and dried in the sun on a flat surface. The press consisted of some wooden boards on which stones were placed that served to exert pressure.

- It was smoothed and polished with an ivory instrument or a shell to prevent ink from smearing when writing.

- Afterwards, some leaves were glued together, forming rolls on a wooden, ivory or bone rod. The glue was made up of water, flour, and vinegar. The right edge of each sheet was superimposed on the next to better consolidate the suture line between the two and favor the passage of the quill from one sheet to another.